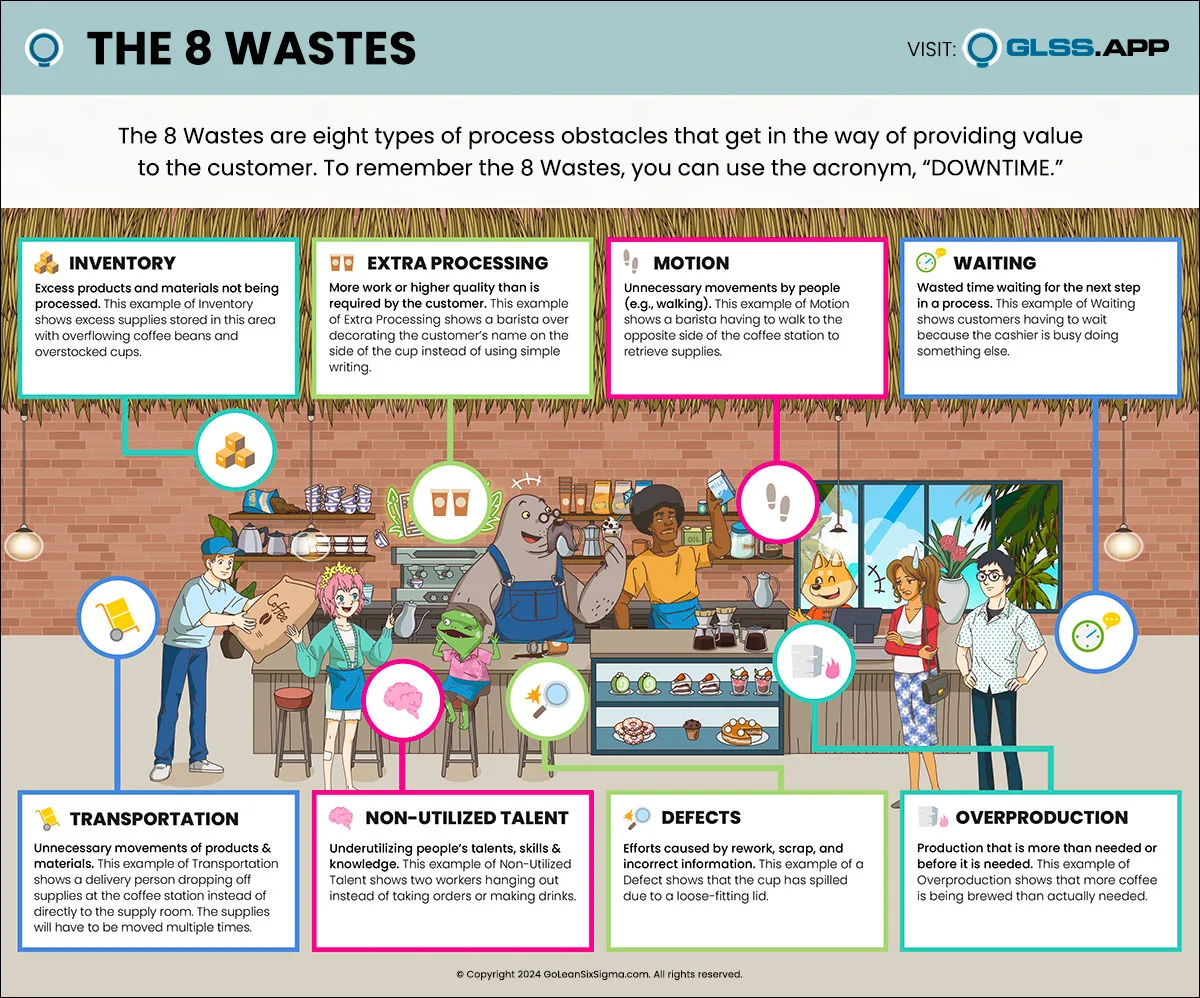

8 Forms Of Waste - You will also be able to identify examples of these. Using the acronym downtime is a great way to remember what the wastes are: Each type of waste is an inefficiency that costs your. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects. Learn what they are and how to reduce them to achieve efficiency and. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. They are often referred to by the. Timwoods represents 8 forms of waste in processes. Identifying and addressing these wastes is fundamental to lean. By the end of this article, you will have a clear understanding of each of the 8 wastes.

Timwoods represents 8 forms of waste in processes. Each type of waste is an inefficiency that costs your. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects. By the end of this article, you will have a clear understanding of each of the 8 wastes. Identifying and addressing these wastes is fundamental to lean. Using the acronym downtime is a great way to remember what the wastes are: They are often referred to by the. You will also be able to identify examples of these. Learn what they are and how to reduce them to achieve efficiency and. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types.

They are often referred to by the. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Learn what they are and how to reduce them to achieve efficiency and. You will also be able to identify examples of these. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects. Each type of waste is an inefficiency that costs your. Using the acronym downtime is a great way to remember what the wastes are: Timwoods represents 8 forms of waste in processes. Identifying and addressing these wastes is fundamental to lean. By the end of this article, you will have a clear understanding of each of the 8 wastes.

8 Wastes Of Lean Posters And Banners From Fabufacture vrogue.co

Learn what they are and how to reduce them to achieve efficiency and. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Timwoods represents 8 forms of waste in processes. By the end of this article, you will have a clear understanding of.

What Are The 8 Types Of Waste at Eldon Berthold blog

They are often referred to by the. Learn what they are and how to reduce them to achieve efficiency and. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects. You will also be able to identify examples of these. Identifying and addressing these wastes is fundamental to lean.

8 Forms of Waste (Downtime) Poster 22" X 28", Made in The USA Process

You will also be able to identify examples of these. Each type of waste is an inefficiency that costs your. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Using the acronym downtime is a great way to remember what the wastes are: By the end of this article, you will have a clear understanding.

LEAN Eight Forms of Waste PDF

Timwoods represents 8 forms of waste in processes. Identifying and addressing these wastes is fundamental to lean. You will also be able to identify examples of these. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. They are often referred to by the.

Learn the 8 Wastes of Lean Continuous Process Improvement

You will also be able to identify examples of these. Each type of waste is an inefficiency that costs your. Identifying and addressing these wastes is fundamental to lean. Timwoods represents 8 forms of waste in processes. By the end of this article, you will have a clear understanding of each of the 8 wastes.

8 Wastes of Lean Identify and Eliminate Waste in Your Workflow

You will also be able to identify examples of these. Using the acronym downtime is a great way to remember what the wastes are: Identifying and addressing these wastes is fundamental to lean. By the end of this article, you will have a clear understanding of each of the 8 wastes. They are often referred to by the.

8 Forms of Waste Poster Lean for Business, Office, Wall Art, Décor

They are often referred to by the. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. By the end of this article, you will have a clear understanding of each of the 8 wastes. Identifying and addressing these wastes is fundamental to lean. Each type of waste is an inefficiency that costs your.

Antonio Donato Pellegrino on LinkedIn Lean six sigma 8 Types of Waste.

You will also be able to identify examples of these. Learn what they are and how to reduce them to achieve efficiency and. They are often referred to by the. By the end of this article, you will have a clear understanding of each of the 8 wastes. Using the acronym downtime is a great way to remember what the.

8 Wastes of lean manufacturing infographic presentation template with

Learn what they are and how to reduce them to achieve efficiency and. They are often referred to by the. Identifying and addressing these wastes is fundamental to lean. By the end of this article, you will have a clear understanding of each of the 8 wastes. Each type of waste is an inefficiency that costs your.

8 Forms of Waste by McKinsey Alum Free Templates

As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. Timwoods represents 8 forms of waste in processes. By the end of this article, you will have a clear understanding of each of the 8 wastes. Using the acronym downtime is a great way to remember what the wastes are: Each type of waste is an.

By The End Of This Article, You Will Have A Clear Understanding Of Each Of The 8 Wastes.

You will also be able to identify examples of these. As mentioned previously in lean six sigma, wastes are categorized into eight distinct types. They are often referred to by the. Learn what they are and how to reduce them to achieve efficiency and.

Identifying And Addressing These Wastes Is Fundamental To Lean.

Using the acronym downtime is a great way to remember what the wastes are: Timwoods represents 8 forms of waste in processes. Each type of waste is an inefficiency that costs your. The seven wastes are transportation, inventory, motion, waiting, overproduction, overprocessing and defects.